rubber liner hardness for ball mill

Si vous souhaitez en savoir plus sur nos concasseurs et broyeurs industriels, envoyez un e-mail [email protected]

Si vous souhaitez en savoir plus sur nos concasseurs et broyeurs industriels, envoyez un e-mail [email protected]

RELATED MATERIALS

Three factors that determine the wear life and performance of mill

metal liners or composite rubber liners with hard cast inserts on the mill shell. However, the rods can move sideways and act as battering rams on the heads, so the head liners should always be fully metallic, preferably of a more impact-resistant alloy. Ball mill In

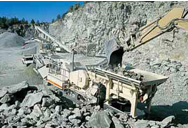

Matériel de traitement:Bentonite,construction waste,River,Stone,coal

capacity:T/H

Finesse du produit fini:0-10mm,10-20mm,20-40mm

TEKNIKUM® Rubber Mill Linings

The Rubber Mill linings made from Teknikum TRL11 and TRL18 compounds are best suited for primary and secondary stage AG/SAG and ball mills stage grinding processes.

Matériel de traitement:Bentonite,construction waste,River,Stone,coal

capacity:T/H

Finesse du produit fini:0-10mm,10-20mm,20-40mm

Ball Mill Liners for Mineral Beneficiation - Polycorp

Rubber Liners in ball mills up to 24ft/7.3m in diameter, and has supplied Mill Liners for more than 300 mills worldwide. Custom Designed Mill Liners p PolyStl™ Liners p

Matériel de traitement:Bentonite,construction waste,River,Stone,coal

capacity:T/H

Finesse du produit fini:0-10mm,10-20mm,20-40mm

CAS CONNEXES

-

perles en pierre de rubis en cristal

-

pdf pierre de concassage machine i afrique du sud

-

Conception et coût du broyeur à boulets

-

basalte Congo fabricant de concasseur

-

co251t du projet de fabrication de sable artificiel

-

procédure de remplacement de roulements à à tourillons des usines de ciment

-

broyeur de m226choire usagé 224 vendre en inde

-

usines complètes de carrière en pierre à vendre